Contents

List of Mechanical Properties of Materials

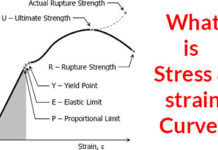

This is the list of mechanical properties of the material and these are related to the behavior of a material under load or stress in tension, compression or shear.

These properties are determined by performing various engineering tests with the proper setup. The common mechanical properties are tensile strength, elastic limit, creep strength, stress rupture, fatigue, ductility, impact strength (toughness and brittleness), hardness and modulus of elasticity. Generally, the strain may elastic and it present only during stressing or plastic deformation.

These mechanical properties are helpful to know that if a material can be manufacture in the required shape and what is the mechanical resistance.

For any material mostly mechanical and physical are used. Here we provide information about mechanical properties. The modulus of the elasticity is considered to be a physical property of the material as it is an inherent property that cannot be changed by heat treatment or cold working. Below are the mechanical properties of the material.

Read Also: Top Ten Strongest Metal on Earth13 Mechanical Properties of Material

Strength

Strength is a mechanical property of the material that is resistant to deformation load.

The strength is the capacity to withstand the destruction under the external loads.

Stronger the material withstands more load.

Elasticity

The elasticity is the ability of material or object to get back into its original shape after a stretch or compress.

If the load is applied to the material, the load makes material deform.

Elasticity is the material got its shape back when stress or load is released.

The heat-treated springs, rubber is the known example of the elastic materials.

Plasticity

It is the property of the material which got deformation permanently under load.

This will only take place after the elastic range has been exceeded.

The plasticity in the structural materials is called yield, plastic flow, and creep.

Materials like clay, lead become plastic at room temperature where steel has plasticity at a very high temperature.

Hardness

It is the resistance of material for force penetration or bending.

Hardness is the property of a material that resists from scratching, abrasion, cutting or penetration.

The material got hard by the quenching process.

Toughness

Toughness is the property of a material that withstands to shock or impact.

Brittleness is the opposite of toughness.

Toughness is like a combination of strength and plasticity.

The Manganese steel, wrought iron, mild steel, etc. are some examples of tough materials.

Brittleness

It is the property of a material that withstands for permanent deformation.

The cast iron, glass is brittle materials.

These materials are break than the bend with impact or shock.

The brittle metals have high compressive strength but low tensile strength.

Stiffness

Stiffness is the mechanical property.

It is the resistance of a material to elastic deformation or deflection.

The material has light deformation under the load has a high degree of stiffness.

Stiffness is very important in many engineering applications so modules of is often to the primary property to select the material.

Ductility

It is the property of the material which turn material into thin wire.

The mild steel, copper, aluminum are the examples of the ductile material.

Malleability

It is a property of a material that allows the material to be hammered or rolled into sheets of sizes and shapes.

Aluminum, copper, tin, lead are examples of malleable metals.

Cohesion

This is a mechanical property where a solid body resists from being broken into a fragment.

Impact Strength

It is the ability of a material to resist against sudden loads.

Fatigue

It is a mechanical property of a material where there is repeated straining action which causes strain or break of material.

The fatigue is used to describe as fatigue of material under repeatedly applying forces.

Creep

It is the slow and progressive deformation of material at a constant force.

Simple creep deformation is viscous flow.

There are metals which have low creep at high temperature and a material like plastic, rubber, and other information materials are temperature sensitive to creep.

The force required for strain at constant temperature is called creep strength.

This is the information about the mechanical properties of materials.

🔔We hope this information will help you. For more new information click on the notification button and get regular updates from Unbox Factory.

Now if you find this information helpful, share it with your friends, family, and colleagues.

If you like this post, let us know by comment below, if you want to add-on information about this topic, comment the information. We will consider the information if it is relevant.

Thank you for reading.