Contents

- 1 What is the Shaper Machine?

- 1.1 First What is Shaper Machine?

- 1.2 What is Machine Tool?

- 1.3 Who invented the Shaper Machine?

- 1.4 What is the working principle of the Shaper Machine?

- 1.5 Main Parts

- 1.6 Mechanism of Shaper Machine

- 1.7 Based on Table Design

- 1.8 Based on Ram Travel

- 1.9 Based on the Driving Mechanism

- 1.10 Crank Type Shaper

- 1.11 Gear Type Shaper

- 1.12 Based on Cutting Stroke

- 1.13 Advantages

- 1.14 Disadvantages

- 1.15 Applications

What is the Shaper Machine?

You will easily find a shaper machine in many mechanical workshops and also in various manufacturing industries. The shaper machine plays an important rule in manufacturing various parts, jobs, etc.

So, without wasting time let’s started what is shaper machine and how it works.

First What is Shaper Machine?

The shaper machine is a type of machine tool which uses the relative motion between workpiece and cutting tool. This machine has linear motion and cuts in a linear toolpath. The cut made by the machine is similar to a lathe machine. The lathe machine makes the helical cut while the shaper machine makes a linear cut.

What is Machine Tool?

The word Machine Tool may new for some readers so what is it?

A machine tool is a machine that is used for shaping the metal or any rigid material. It is similar to the wood shaper.

The wood shaper is used to get the required shape and size of the wood. In simple words, a wood shaper is a woodworking tool. It is known as a shaper in North America and a spindle molder in the United Kingdom.

When you are learning about the manufacturing process, you may hear the metalworking planer. The shaper machine we are talking about here is similar to that metalworking planer. The basic difference between the shaper machine and metalworking planer is the size.

The metalworking planer is bigger in the size than the shaper machine. The cutting tool is move in the shaper machine and the workpiece is move-in metalworking planer.

Read Also: CNC MachineWho invented the Shaper Machine?

An English engineer named Samuel Bentham an engineer and very known naval architect. He was inverter of many mechanical engineering items. He invented the shaper machine in 1791 and 1793. This machine is common in the mid-19th century and early 20th century.

In the current era, there are many machines are available like CNC machines, milling machines, grinding machines. Also, the broaching machine is used instead of a shaper machine.

The question may arise that the shaper machine can easily replace by modern machines then why it is still used in the manufacturing process?

The main function of the shaper machine is it cut the part perfectly. The machine has a strong built and requires less maintenance and if it is maintaining proper than it can work for years without any problem.

What is the working principle of the Shaper Machine?

Before starting the working principle of the shaper machine first discuss the cutting tool. The function of the cutting tool is to remove the material from a workpiece.

There is a single-point cutting tool used in a this machine and it has only one cutting edge. The turning tool is the best example of a single-point cutting tool. It is placed in the tool holder and also mounted on the ram.

The workpiece is clamped directly on the table for machining and it may support at another end. Ram is exhibiting the reciprocating motion. And the cutting tool holder is moved backward and forward on the surface of the workpiece.

Many of you think that the ram rotates and cutting in strokes. And it is depending on the shapes. The cutting takes place in forwarding stroke in a standard shaper machine and the backward stroke is considered to be idle.

The cutting tool got motion from the quick return mechanism and cutting depth is achieved by movement of the tool. Feed motion follows the pawl and ratchet mechanism.

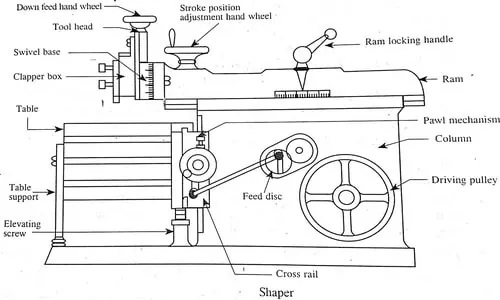

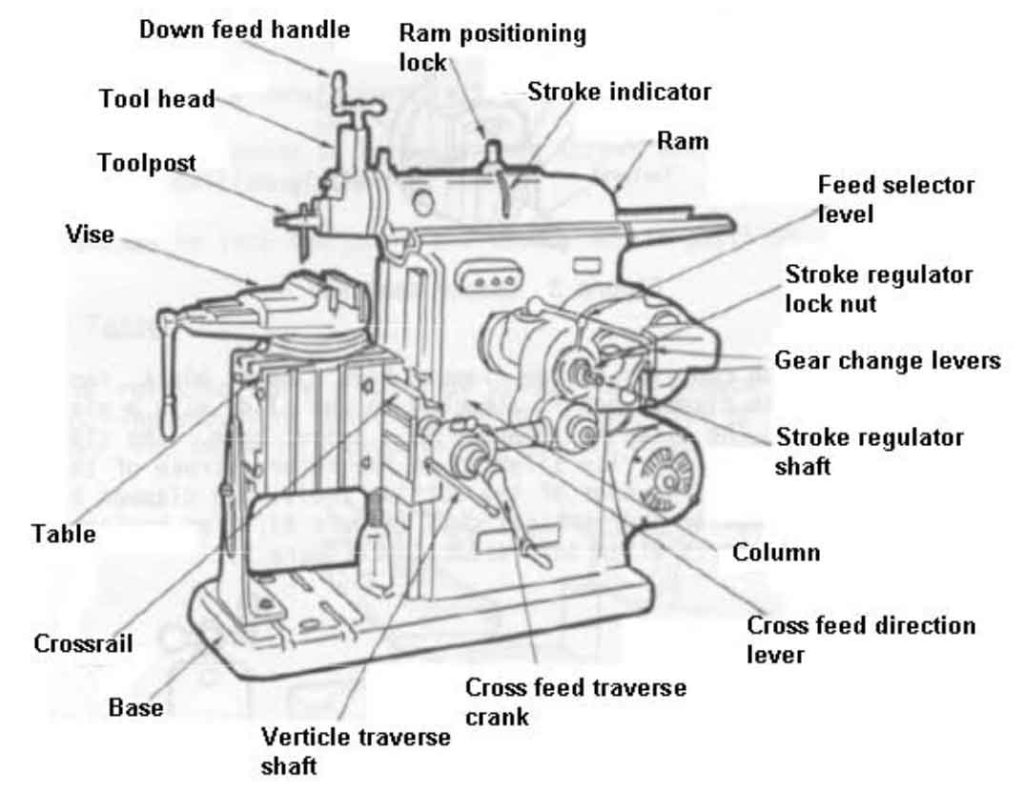

Main Parts

The shaper machine has mainly five parts are:

- Base

- Column

- Table

- Ram

- Cross-rail

Base

- It is the most important part of the shaper. The base provides support to other machining tools. The base is hollow and made of cast iron. The hollo shape minimizes the vibration.

- The construction of the base is to handle the load of the machine.

Column

- It is mounted on the base and made of cast iron.

- There are two guideways provided on the column on which the ram reciprocates.

- Column supports the reciprocating ram and worktable.

Table

- The swivel of the table takes place on any angle.

- The table is clamped to become rigid to handle heavy applications.

- It is a very important part of the shaper machine.

- There are T type bolts used for clamping on the top and bottom side.

Ram

- There are guideways present on column Ram reciprocates and carry the head of the tool with a single-point cutting tool.

- The cutting action takes place on the forward stroke of ram due to the tool head present in the clapper box.

- The depth of the cut is given by the down feed screw.

Cross-rail

- It is mounted on the surface of the table where the saddle is there.

- With the elevating screw and cross-rail, the table got the vertical motion.

- There is a horizontal motion of the table by moving the saddle with the cross-feed screw.

Mechanism of Shaper Machine

When you studying any mechanical system, it is necessary to understand what is a mechanism and how it works. As we discuss above the shaper machine works on a Quick return mechanism.

The reciprocating motion of the ram and quick return mechanism is achieved by below four mechanisms:

- An automatic table feed mechanism

- Whitworth quick return mechanism

- Hydraulic shaper mechanism

- Crank and slotted mechanism

1. Automatic Table Feed Mechanism

This is the simple mechanism in the shaper machine. The automatic table feed mechanism is simple and it is started by activating a ratchet wheel and it is mounted at cross-feed screw.

This mechanism ensures the same motion of cross-feed screw after every stroke.

2. Whitworth Quick Return Mechanism

The Whitworth quick return mechanism is used in slotting and shaper machine. The most important factor consider with this is time. This requires more time than the return stroke and there is cutting in the forward stroke.

The mean speed of the ram during cutting stroke is less than the mean speed of ram in the return stroke.

3. Hydraulic Shaper Mechanism

The hydraulic shaper mechanism, the cutting tool moves forward or backward with the help of piston which is inside the cylinder.

The valve, pressure and oil play are very important. Here the cutting speed can be adjusted with a throttle valve. The throttle valve controls the flow of the oil. The uniform pressure is maintained in cutting stroke for getting machining effect.

4. Crank and slotted link Mechanism

The crank and slotted link mechanism, power is transmitted to bull gear through pinion and this pinion receives power from the individual motor.

Speed is changeable of bull gear by different combinations of gearing systems.

Working of Shaper Machine

The workpiece is mounted on the table and the table is rigid and box-shaped and placed in front of a machine or near the machine.

The height of the table is easily adjustable and it is adjusted to match the workpiece. The motion of the table is control manually. Have you ever thought about any other way for the motion of the table?

The table is equipped with an automatic feed mechanism and works with a feed screw. This is for cutting and the ram is adjustable for stroke.

Types of Shaper Machine

The shaper machine has different types:

- Based on Table Design

- Based on Ram Travel

- On the type of driving Mechanism

- Based on Cutting Stroke

Based on Table Design

Universal Shaper Machine

The table moves in the inclined direction and also horizontal and vertical. And the shaper machine can swivel with its axis. This is known as the universal shaper machine as it is used for universal applications.

Standard Shaper Machine

There are only two components in standard shaper machines are horizontal and vertical and these directions are used for giving the feed.

Based on Ram Travel

Vertical Shaper

The ram reciprocates in the vertical direction in the vertical shaper machine. Now if you want to cut the internal surface then the vertical shaper is perfect. And the workpiece can move in any given direction.

Horizontal Shaper

There is a reciprocating ram in the horizontal shaper and the ram moves in the horizontal direction. It is widely used for the generation of flat surfaces and other applications.

Based on the Driving Mechanism

Hydraulic Shaper

As the name suggests for the machining the hydraulic mechanism is required. The high-pressure oil is used in the machine. The high-pressure oil works on both sides of the piston which causes the reciprocate the machine. This reciprocating motion moves the ram. The main benefit of this machine is we can maintain the constant cutting speed.

Crank Type Shaper

The crank type shaper machine is widely used shaper machines that execute reciprocating machining.

Gear Type Shaper

This gear type machine, ram is reciprocating in a machine. Its transverse speed of machine depends on several gears.

Based on Cutting Stroke

Draw Cut Type

The metal is removed in the backward position of the ram in draw cut type machine.

Push Cut Type

The metal is removed in the forward position of the ram in the push cut shaper machine and it is a widely used shaper machine.

Advantages

- The advantage of the shaper machine is it has low tooling cost. There is a single-point cutting tool is used in the shaper machine which is inexpensively and it is easily available. With the single point cutting tool, the machining can be done efficiently without adding more cost.

- The cutting stroke has a definite stopping point which is helpful in machining.

- The benefit of a this machine is it is easy to handle. With the minimum knowledge of the machine as an operator can run the machine easily. There are some skills required to operate the machine so an experienced worker can handle the machine flawlessly.

- This can use for flat or angular surfaces.

- Machining can be done easily without any problem.

Disadvantages

- This machine took more time for machining. There are cutting and return strokes in the machining, it takes longer time for machining than the milling and other machines.

- There is only one tool is used for cutting. You cannot cut the workpiece in both directions.

- Cutting speed is low in the shaper machine.

Applications

This is used for machining straight and flat surfaces.

For gear teeth and other internal splines.

For the blind holes, the gear tooth cutting can be done.

Used for dovetail sliders.

This is a perfect device to get the smoothness of a rough surface.

It is also used for electric discharge machining.

In the irregular shape holes with tight corners cannot be made with milling or with other machining processes. The machine can create these types of hole.

This is the information about various shaper machine.

🔔We hope this information will help you. For more new information click on the notification button and get regular updates from Unbox Factory.

Now if you find this information helpful, share it with your friends, family, and colleagues.

If you like this post, let us know by comment below, if you want to add-on information about this topic, comment the information. We will consider the information if it is relevant.

Thank you for reading.