Contents

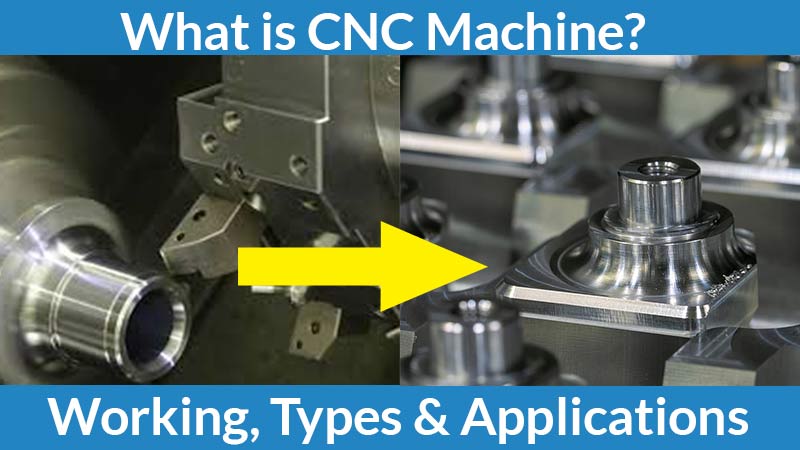

What is a CNC Machine?

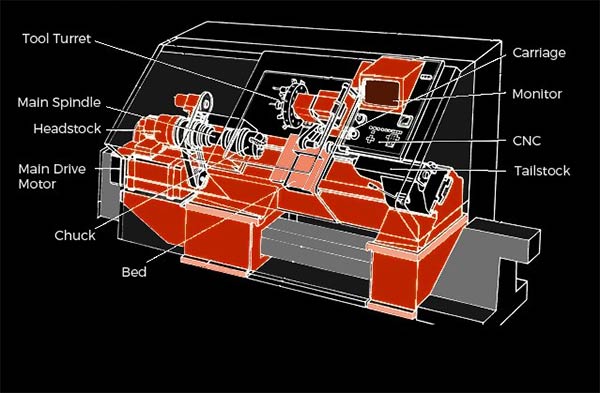

First, understand what is CNC machine. The CNC stands for Computer Numerical Control. When the computers are used to control a Numerical Control (NC) machine tool then the machine is called a CNC machine. In simple words, the use of computers to control machine tools like lathe, mills, shaper, etc. is called the CNC machine.

Cutting operations performed by CNC is called CNC machining. The CNC machining, programs are designed or prepared first and then it is fed to the CNC machine. As per the program, the CNC controls the motion and speed of the machine tools.

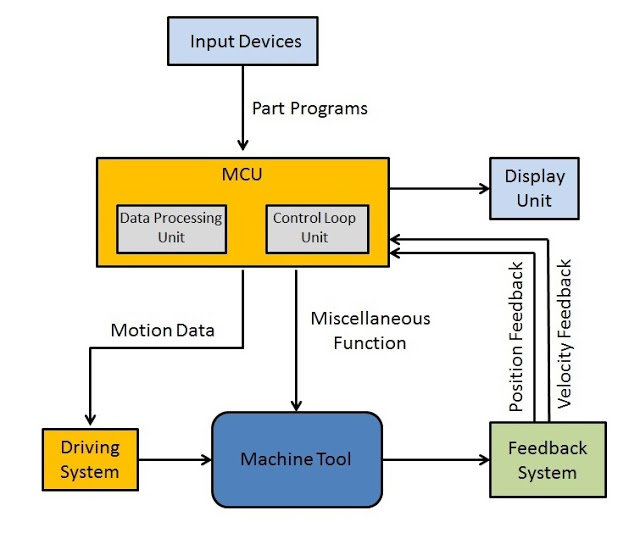

Read Also: What is a CNC Machining?Block Diagram of CNC Machine

Parts of CNC Machine

Main parts of CNC machines are

Input Devices

These devices are used to input the part program in the CNC machine. There are mainly three input devices are used punch tape reader, magnetic tape reader and computer via RS-232-C communication.

Machine Control Unit (MCU)

It is the main part of the CNC machine. This performs all the controlling action of the CNC machine, and various functions of MCU are

- Reads the coded instructions fed into it.

- Decodes the coded instruction.

- MCU implements interpolation (linear, circular and helical) to generate axis motion commands.

- Feeds the axis motion commands to the amplifier circuits for driving the axis mechanism.

- Receives the feedback signals of position and speed for each drive axis.

- This implements the auxiliary control functions like coolant or spindle on/off and tool change.

Machine Tool

The CNC machine tool always has a sliding table and a spindle to control the position and speed. The machine table is controlled in the X and Y-axis direction and the spindle is controlled in the Z-axis direction.

Driving System

In the driving system of CNC machine there is amplifier circuits, drive motors and ball lead screw. MCU feeds the signals like the position and speed of each axis to the amplifier circuits. After that, the control signals are increased to actuate the drive motors. The actuated drive motors rotate the ball lead screw to position the machine table.

Feedback System

The feedback system consists of transducers that act as sensors. This is also called a measuring system. This contains position and speed transducers with continuously monitor the position and speed of the cutting tool located. MCU receives the signals from transducers and uses the difference between reference signals and feedback signals to generate the control signals for correcting the position and speed errors.

Display Unit

The monitor is used to displaying the programs, commands and other useful data of the machine.

How CNC Machine Works?

- The part program is inserted into MCU of the CNC.

- MCU processes all the data and according to it the program is prepared and prepares all motion commands and sends it to the driving system.

- Drive system works as the motion commands sent by MCU and drives system controls the motion and velocity of a machine tool.

- The feedback system records the position and velocity measurement of the machine tool and sends a feedback signal to MCU.

- The MCU compared the feedback signals with the reference signals and if there are errors it corrects and sends a new signal to the machine tool for the right operation to happen.

- The display unit is used to see the commands, programs, and other important data and it is the eye of the machine.

Advantages of CNC Machine

This machine can make jobs with high accuracy and with precision than any other manual machine.

It can work for 24 hours a day.

The parts produced by the CNC machine have the same dimension. There is no variation in the parts manufactured in the same machine.

There is no need for highly skilled workers to operate this machine. A semi-skilled worker can run the machine more accurately and precisely.

Operators can easily make changes and improvements and with that reduce time.

This machine can make complex designs with high accuracy in minimum time.

With modern design software, the designer simulates the idea. And there is no requirement to make a prototype or model which saves time and money.

There are fewer workers required to operate a machine which saves the labor cost.

Disadvantages of CNC Machine

Having so many advantages, the machine has some disadvantages too. These are:

The cost of this machine is very high as compared to manually operated machines.

Parts of CNC machines are expensive.

The maintenance cost is high for CNC machines.

The machine requires costly tools to operate.

Applications

The CNC machines are used in almost every manufacturing industry. With the increased demand in the manufacturing industry, the use of CNC is also increased. Machine tools that come with CNC are lathe, mills, shaper, welding, etc. It is widely used in the automotive industry, metal removing industries, fabricating metals, electrical discharge machine industries, wood industries, etc.

This is the information about what is CNC and we also include the CNC parts, CNC diagram, advantage, and disadvantage.

🔔We hope this information will help you. For more new information click on the notification button and get regular updates from Unbox Factory.

Now if you find this information helpful, share it with your friends, family, and colleagues.

If you like this post, let us know by comment below, if you want to add-on information about this topic, comment the information. We will consider the information if it is relevant.

Thank you for reading.