Contents

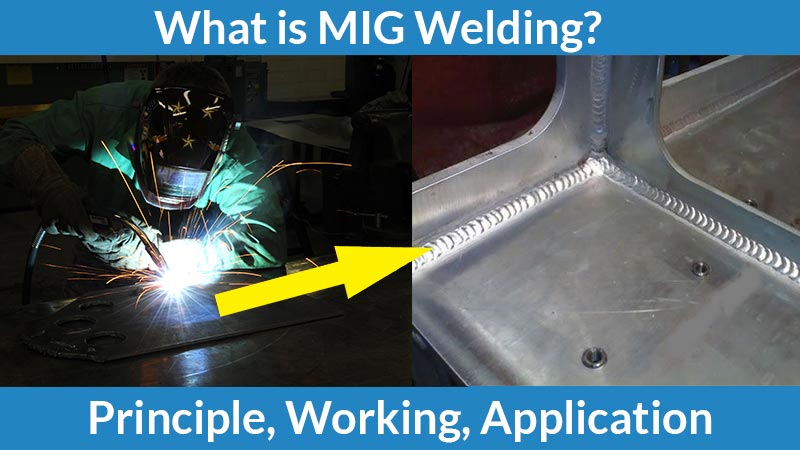

What is MIG Welding?

In this article, we will provide information about Mig Welding. We also provide information about the principle, working, application, pros, and cons of MIG welding. Full form of Mig welding is metal inert gas welding and sometimes it is also known as Gas Metal Arc welding. This is the same as tig welding. The only difference is in the tig welding there is a non-consumable electrode and in the MIG welding, there is consumable electrode wire. Mig welding is an automated or semi-automated arc welding process where inert gases are used as shielding gas and a consumable wire electrode is used. Mig welding was originally developed to weld aluminum and other non-ferrous metals in 1940. As of today, it is used in every industrial process as it has speed, easy to operate qualities. It is widely used in sheet metal industries and in automobile industries.

Read Also: Different Types of WeldingPrinciple Welding

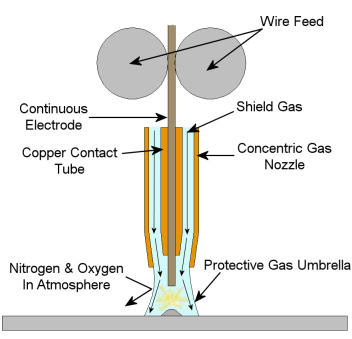

The principle of Mig welding is the same as Tig or arc welding. The basic principle is heat generation due to electric arc. This heat melts the consumable electrode and base plate metal and they make a strong joint. There are also shielded gases are supplied via the nozzle and it protects the weld zone from other reactive gases and gives a good surface finish and a very strong joint.

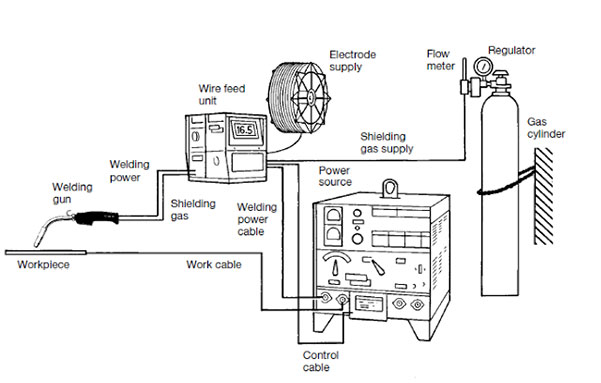

Mig Welding Diagram

Power Source

In the MIG welding process, the DC power supply is used in reverse polarity. The reverse polarity is the electrode or electrode wire is connected to a positive terminal and work piece to the negative terminal. The principle of an electric circuit is 70% of heat is always on the positive side. The reverse polarity ensures that maximum heat transferred to the tool side and it melts the filler metal in the proper way. The straight polarity may cause an unstable arc which results into large spatter. In the power source, there is a power supply, a transformer, a rectifier that converts AC to DC and other electronic controls. This controls the current supply according to the welding requirement.

Wire Feeder System

In MIG welding, there is a continuous need for a consumable electrode supply for welding two plates. The consumable electrode is in the form of wire. A wire is supplied continuously by the wire feed mechanism. This controls the speed of the wire and pushes wire from welding torch to the welding area. This is available in different shapes and sizes. In this system there is a pool holder, driving motor, set of driving rollers and wire feed controls. The speed of wire feed is directly control by the current supply via the power supply. In this, if the wire feeding speed is high required more current in the welding zone for producing heat to melt it.

Welding Torch

The torch is slightly different from used in TIG welding. The torch has a mechanism that holds the wire and supply continuously with the help of wire feed. The front end of the torch is fitted with the nozzle. The inert gases are supplied through inert gases. These gases create a shield around the weld zone and protect it from oxidization. This welding torch is air or water-cooled according to requirement. The torch is water-cooled for high current supply and air-cooled for low supply.

Shielding Gases

The main function of shielding gases is to protect the weld area from other reactive gases like oxygen as it directly affects the strength of the welding joint. These gases form a plasma that is helpful in welding. The gas choice is depending on the welding material. Generally, the Argon, helium and other inert gases are used as shielding gases.

Regulators

As the name suggests, it is used to regulate the flow of inert gases from the cylinder. Inert gases are filled into a cylinder at high pressure and it cannot be used at such high pressure and to control the supply. The regulator is used to lower the pressure as per the requirement of welding.

How Mig Welding Works?

In this process first the high voltage current change into DC current supply with the high current at low voltage. This transformed current passes through the welding electrode.

The consumable wire is used to an electrode. An electrode is connected to the negative terminal and workpiece from the positive terminal.

The intense arc will generate between the electrode and workpiece because of the power supply. This arc produces heat which melts electrode and base metal. The most of electrode is made with the base metal to make a uniform joint.

The arc is shielded by shielding gases. These gasses protect the weld from other reactive gases which could damage the welding joint.

The electrode in joint travel continuously for making a weld. The direction of travel should keep between 10-15 degrees and the fillet joints angle should be 45 degrees.

Read Also: TIG WeldingWhere Mig Welding is used?

- Mig welding is suited for the fabrication of sheet metal.

- The metals can weld through this process.

- Mig welding is also suitable for deep groove welding.

Advantages of Welding

- It has a high deposition rate.

- It is fast compared to arc welding as it supplies filler material continuously.

- Weld making with MIG welding is clean with improved quality.

- It has no slag formation and has low weld defects.

- With this weld, MIG welder can make deep groove weld and it is also easily automated.

Disadvantages of MIG Welding

- It is not used to welding to reach portions.

- It has a high setup cost.

- MIG weld cannot be done outdoor as the wind can damage the gas shield.

- For MIG welding welder should be experienced.

This is the information about MIG Welding. We also provide information about MIG Welding, it’s a principle, working, parts, applications, and its advantages and disadvantages.

🔔We hope this information will help you. For more new information click on the notification button and get regular updates from Unbox Factory.

Now if you find this information helpful, share it with your friends, family, and colleagues.

If you like this post, let us know by comment below, if you want to add-on information about this topic, comment the information. We will consider the information if it is relevant.

Thank you for reading.