Contents

TIG Welding | Principle, Working, Applications, Advantages and Disadvantages

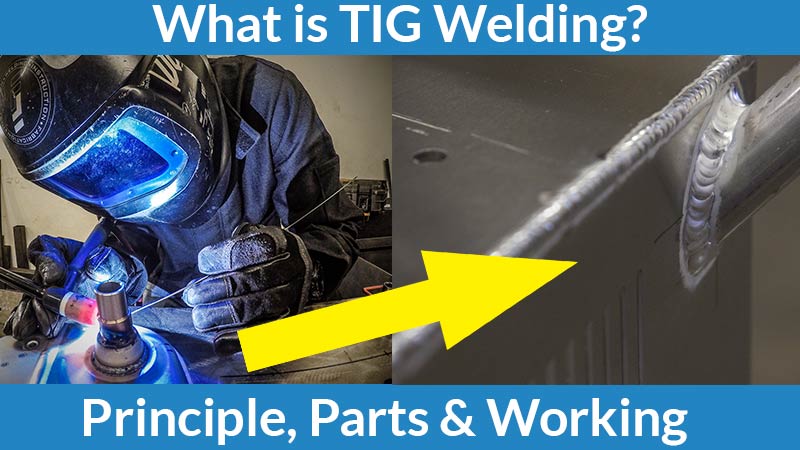

Here we will provide information about what is TIG Welding, how it works, Principle, advantages, and disadvantages. The full form of TIG is Tungsten Inert Gas welding or it is also known as tungsten arc welding. In the TIG welding process, the heat is required for forming a weld and it is provided by an intense electric arc and it is formed between a tungsten electrode and workpiece. There is a non-consumable electrode is used and it does not melt. Generally, the no filler material is required in this welding and if required the welding rod is fed to the weld zone directly and it melted with a base metal. Tig welding is widely used to weld aluminum alloy.

Read Also: Different Types of WeldingPrinciple

The principle of tig welding is the same as arc welding. In the tig welding, the high-intensity arc is produced between the tungsten electrode and workpiece. In the TIG welding, the workpiece is connected to the positive terminal and the electrode is connected to the negative terminal. The arc produces massive heat energy which is used to join metal plate. The shielding gas is used and it protects the weld surface from oxidization.

What is used in TIG Welding?

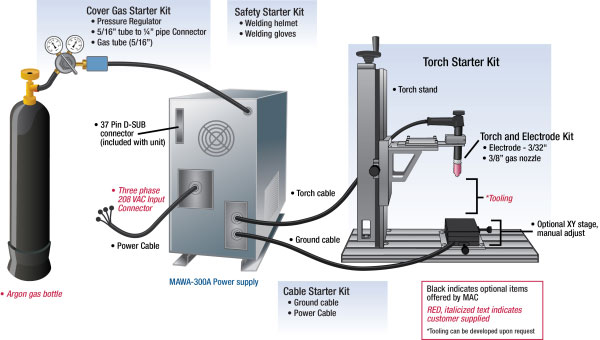

Power Source

The main part of welding is a power source. There is a high current power source is needed for TIG welding. This welding uses both AC and DC power sources. The DC current is used for stainless steel, Mild Steel, Copper, Titanium, Nickel alloy, etc. AC current is used for aluminum, aluminum alloy, and magnesium. In the power source, there is a transformer, a rectifier, and electronic controls. The 10-35 V and 5-300 A current required for arc generation.

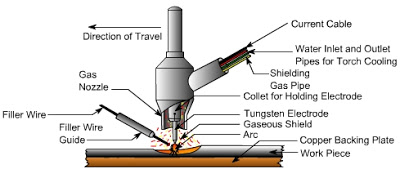

TIG Torch

Tig torch is most important in TIG Welding. The torch has three main parts tungsten electrode, collets, and nozzle. The torch has either water-cooled or air-cooled. The collet holds the tungsten electrode. They are available in various diameters according to a diameter of the tungsten electrode. The arc and shielded gases are flowing into the welding zone via a nozzle. The cross-section of the nozzle is small which gives high intense arc. The nozzle has to replace time to time as it damages with an intense spark for better performance.

Shielding Gas

Generally, argon and other inert gases are used as shielding gas. The importance of shielding gas is it protects the weld from oxidization. The shielded gas protects the welding area from oxygen and other gases from the atmosphere. There is different inert gases are used according to metal. The shielded gases are regulated by the system into welding.

Filler Material

For welding of thin sheets, no filler is used but thick weld filler material is used. A filler material is used in the form of rods and feeds directly during welding manually.

How Tig Welding Work?

The working of TIG Welding is described below.

In the process, the low voltage high current supplied by a power source to welding or tungsten electrode. The electrode is connected to a negative terminal and the workpiece is connected to a positive terminal.

The supplied current form a spark between the tungsten electrode and the workpiece. Tungsten is a non-consumable electrode that gives a highly intense arc. This arc produces intense heat and it melts base metal which forms a welding joint.

Shielded gases like argon, helium is supplied via pressure valve and regulating valve to the welding torch. The shielded gases form a shield around the weld and do not allow to enter oxygen and other reactive gases. Also, these shielded gases create a plasma that increases the heating capability of arc for better welding.

While welding thin material there is no filler is required but to make thick joints require some filler material in the form of the rod to fed manually by a welder into welding.

Read Also: MIG WeldingApplications

TIG Welding is widely used to weld aluminum and aluminum alloys.

It is also used to weld stainless steel, carbon base alloy, copper base alloy, nickel base alloy, etc.

It is also used to weld dissimilar metals.

TIG welding is widely used in aerospace industries.

Advantages of TIG Welding

- TIG Welding provides a stronger joint compared to shield arc welding.

- The joint made with tig welding is corrosion resistant and ductile.

- With this welding, a wide verity of joint designs can form.

- This welding type doesn’t require a flux.

- The process is automated.

- This is suitable for thin sheets.

- It provides excellent surface finish as there is almost no metal splatter.

- The flawless joint can create due to a non-consumable electrode.

- A welder has more control over welding than other welding types.

- It works on both AC and DC current as a power supply.

Disadvantages of TIG Welding

- It can weld up to a thickness of about 5 mm.

- Require high skill labor.

- It has a high initial or setup cost compare to arc welding.

- This is a slow welding process.

This is the information about what is TIG Welding, its principle, application, working, advantages and disadvantages.

🔔We hope this information will help you. For more new information click on the notification button and get regular updates from Unbox Factory.

Now if you find this information helpful, share it with your friends, family, and colleagues.

If you like this post, let us know by comment below, if you want to add-on information about this topic, comment the information. We will consider the information if it is relevant.

Thank you for reading.