Contents

- 1 What are the main parts of the Milling Machine?

- 1.1 Types of Milling Machine

- 1.2 Different Milling Machine Operations

- 1.2.1 1. Face Milling

- 1.2.2 2. Side Milling

- 1.2.3 3. Plain Milling

- 1.2.4 4. Straddle Milling

- 1.2.5 5. Angular Milling

- 1.2.6 6. Gang Milling

- 1.2.7 7. Form Milling

- 1.2.8 8. Profile Milling

- 1.2.9 9. End Milling

- 1.2.10 10. Saw Milling

- 1.2.11 11. Milling Key Ways, Grooves and Slots

- 1.2.12 12. Gear Milling

- 1.2.13 13. Helical Milling

- 1.2.14 14. Cam Milling

- 1.2.15 15. Thread Milling

In this article, we have provided information about what is milling machine, types of milling machine, parts of milling machine and operation of milling machine. Milling machines provide support to the manufacturing industries. The milling machines can perform almost every milling operation like gear milling, thread milling, angular milling, etc.

First, understand What is Milling Machine?

The milling machines are used to remove metal from the workpiece to get the desired shape with the help of a revolving cutter called known as a milling cutter. This is used on flat, rough and irregular surfaces and it is completed by place the workpiece opposite the rotating milling cutter.

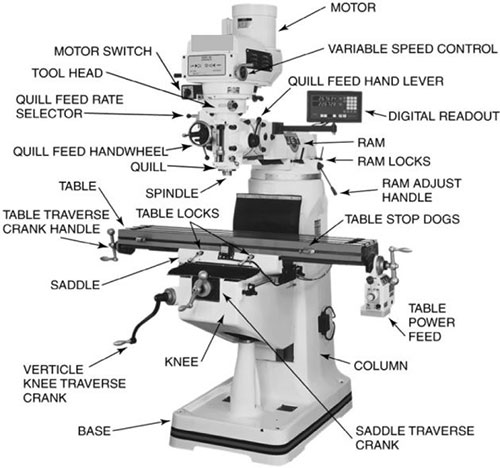

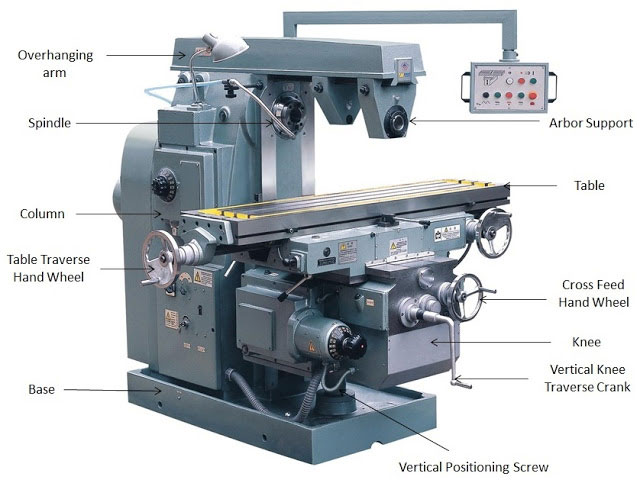

What are the main parts of the Milling Machine?

Vertical Milling Machine

Horizontal Milling Machine

1. Column and Base

Column and base provide support for the other parts of the milling machine.

- There is an oil reservoir and pump in the column to lubricate the spindle.

- The column rests on the base and also it has a coolant reservoir and a pump to provide coolant in machining operations.

2. Knee

Saddle and table have the support of casting. The gearing mechanism is enclosed within the knee.

- The knee is fastened to the column by dovetail ways.

- It is supported and adjusted by a vertical positioning screw also known as an elevating screw.

- The use of the elevating screw is to adjust the knee up and down by raising or lowering the lever with the help of hand or power feed.

3. Saddle and Swivel Table

The saddle is on the knee and supports the table. Saddle slides on horizontal dovetail on the knee and dovetail are parallel to the axis of the spindle (in horizontal milling m/c).

- Swivel table is attached to the saddle that swiveled (revolved) horizontally in both directions.

4. Power Feed mechanism

The power feed mechanism is in the knee. The power feed mechanism is used to control in longitudinal (left and right), transverse (in and out) and vertical (up and down) feeds.

- For the desired rate of feed on the machine, the feed selection lever is placed to indicate on the feed selection plates.

- For some universal knee and column milling machine, feed is obtained by turning the speed selection handle till the required rate of feed is shown on feed dial.

- Almost in every milling machine, there is a rapid traverse lever which is used when a temporary increase in the speed of the longitudinal, transverse or vertical feeds is required. This lever is used when the operator is aligning or positioning the work.

5. Table

The table is a rectangular casting that is present on the top of the saddle.

- The table is used to hold the work or for work holding devices.

- There are several T-slots to hold work and work holding devices (jigs and fixtures).

- It can be operated by hand or by power. For moving the table by hand, engage and turn the longitudinal hand crank. For move, it by power, engage and longitudinal direction feeds control lever.

6. Spindle

The spindle is used to holding and drives the cutting tools of the milling machine.

- It is mounted on the bearings and has the support of the column.

- The spindle is driven by an electric motor via gear trains and gear trains are on the column.

- The spindle face lies near the table and having an internal taper machined on it. There are two keys at the front face provides a positive drive for cutter holder or arbor.

- Drawbolt and jamnut secure the holder and arbor in the spindle.

7. Over Arm / Overhanging Arm

Overarm is a horizontal beam and it is on the top face of the column. It may be a single casting and slides on the dovetail ways which is on the top face of the column.

8. Arbor Support

Arbor support is casting with a bearing that supports the outer end of the arbor. It also helps to align the outer end of the arbor with the spindle.

- Arbor support prevents the springing of the outer end of arbor in cutting operations.

- Generally, there are two types of arbor supports used in the milling machines. The first one has a small diameter bearing hole of a maximum diameter of 1 inch. The second one has a large diameter bearing hole of up to 23/4 inch.

9. Ram

The ram is an overhanging arm in a vertical milling machine. The one end of the ram is mounted on the top of the column and the milling head is attached to another.

Read Also: CNC Machine and WorkingTypes of Milling Machine

- Horizontal and Vertical

- Knee-type

- Ram-type

- Manufacturing or Bed-type

- Planer-type

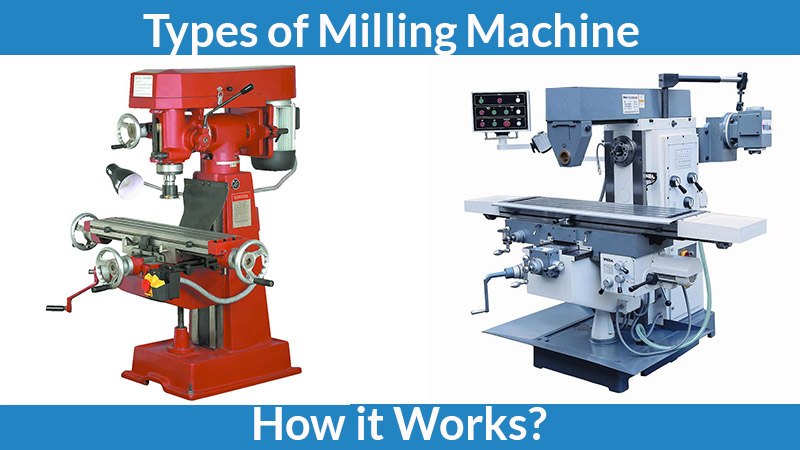

The milling machines are mainly divided into horizontal milling machines and vertical milling machines. There are also other types than the main ones like knee-type, ram-type, manufacturing or bed type and planer-type milling machine.

The most milling machine types have self-electric driven motor, coolant systems, power-operated table feed, and variable spindle speeds.

1. Horizontal Milling Machine

For the horizontal milling machine, the axis of rotation of the spindle is horizontal to the table. It is called a horizontal milling machine as it has a horizontal axis of the spindle.

2. Vertical Milling Machine

The vertical milling machine has the spindle axis perpendicular to the table.

3. Knee-Type Milling Machine

The machine having the knee like projection at the middle is called knee-type milling machine. In the Knee-type milling machine, there is a vertically adjustable worktable resting on a saddle supported by a knee.

4. Ram-Type Milling Machine

The milling machine having ram on the top of the column is called ram-type milling machine. It is generally used in a vertical milling machine. It can be moved on the column in the transverse direction. For example, in and out when operated from the knee side.

Different Milling Machine Operations

There are various milling machine operations used for different kinds of jobs.

1. Face Milling

This makes the flat surface at the face of the workpiece. Face milling is done on the surface of the workpiece which is placed perpendicular to the axis of the cutter. This operation is done performed by face milling cutter mounted on stub arbor.

2. Side Milling

In this process, the flat vertical surfaces produce at the side of a workpiece. This process is done with a side milling cutter.

3. Plain Milling

For the milling of flat surfaces, the axis of the cutter is kept parallel to the surface being milled. It is also known as surface milling or slab milling. The plain milling cutter is used for plain milling.

4. Straddle Milling

In this process, the two side milling cutter is used to machined two opposite sides of a workpiece.

5. Angular Milling

It is used to milling flat surfaces which are neither parallel nor perpendicular to the axis of the milling cutter. It is also known as angle milling. The single angle milling cutter is used to perform this operation.

6. Gang Milling

In this machining process, two or more milling cutters are used together to perform different milling operations simultaneously. The cutters are mounted on the arbor in the gang milling.

7. Form Milling

This operation is used for machining special contour composed of curves, straight lines or entirely of curves at the single cut. The convex, concave and corner rounding milling cutters are used in this operation.

8. Profile Milling

It is used to cut a profile on the workpiece.

9. End Milling

This process is used to produce a flat surface which can be horizontal, vertical and at any angle taking worktable as a reference. The end milling cutters are used in this process.

10. Saw Milling

The saw milling is used to produce narrow grooves or slots on the workpiece.

- This operation is also used for parting off the workpiece into two equal or unequal parts.

- The saw milling cutter is used in this operation.

- In this operation, the width of the cutter is very less than the width of the workpiece.

11. Milling Key Ways, Grooves and Slots

This operation is used to produce keyways, grooves, and slots on the workpiece.

12. Gear Milling

This milling process is used to cut gears on the workpiece. The involute gear cutters are used in this operation.

13. Helical Milling

It is used to produce objects of having a helical design like helical gears, twisted drills, etc. and it is performed on the periphery of a cylindrical workpiece.

14. Cam Milling

This milling operation is used to make cams. These cams are used to open and close the valves in the IC engines.

15. Thread Milling

This operation is used to cut threads on the cylindrical workpiece.

This is the information about Milling Machine and its parts, types, and operations.

🔔We hope this information will help you. For more new information click on the notification button and get regular updates from Unbox Factory.

Now if you find this information helpful, share it with your friends, family, and colleagues.

If you like this post, let us know by comment below, if you want to add-on information about this topic, comment the information. We will consider the information if it is relevant.

Thank you for reading.