Contents

- 1 Jigs and Fixtures | Types, Parts, Advantages, Applications, etc.

- 1.1 Jigs and Fixtures

- 1.2 What is Jig?

- 1.3 What is a Fixture?

- 1.4 Main Elements of jigs and fixtures

- 1.5 Types of Jigs and Fixtures

- 1.6 Types of Fixtures

- 1.7 Difference Between Jigs and Fixtures

- 1.8 Advantages of using Jigs and Fixtures in Mass Production

- 1.9 Advantages of Jigs and Fixtures

- 1.10 Applications of Jigs and Fixtures

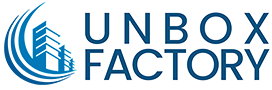

Jigs and Fixtures | Types, Parts, Advantages, Applications, etc.

In this article, we have provided information about what is jigs and fixtures. Also provide information about types of jigs and fixtures, working principles and what is the difference between jigs and fixtures.

Jigs and Fixtures

The jigs and fixtures are helpful for increasing the production of identical parts and reduce the human efforts for producing parts. It is already very important in earlier times that a center lathe is suitable to the machine tools for manufacturing individual parts of different shapes and sizes. For producing similar products in large quantity this is not an economical option.

On the other side, the capstan and turret lathe can easily be programmed for repetition work for multi0cooling arrangement and use of transverse stop and this increases the rate of production.

Though not every type of object can machine on capstan or turret lathe and has to involve the use of drilling, milling, planning, and grinding machines, etc. With the jigs and fixtures, such objects can produce in identical shapes and sizes on large quantities. The jigs and fixtures are used for holding and locating purposes so the repetition work can be done.

Read Also: What is Lathe Machine?What is Jig?

A jig is a device that holds and locates a workpiece and guide and it controls one or more cutting tools. The holding of the work and guiding of the tool is such that they located in true positions to each other.

The jig is a plate, a structure or a box made of meta or for some cases, it is a non-metal handles the components for identical positions one after other and then guiding the tool incorrect positions on work in accordance with drawing, specification or operation layout.

What is a Fixture?

The fixture is a device that holds and locates a workpiece during an inspection for a manufacturing operation. It does not guide the tool.

The fixture is a specially designed to work holding device and it is clamped on the machine and able to hold the work in the position. Tools are set at required positions on work by using gauges or by manual adjustment.

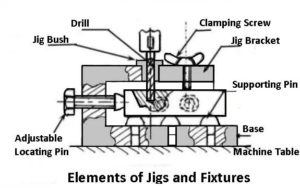

Main Elements of jigs and fixtures

The above are the elements of jigs and fixtures.

Body: It is a plate, box or frame type structure where components are located for machined. The body should be quite sturdy and rigid.

Locating Elements: These elements are located at workpieces in the exact location for cutting tools.

Clamping Elements: These elements firmly secure workpiece in the located position.

Grinding and setting Elements: These elements guide the cutting tool if jig and help in proper tool acting in case of the fixture.

Positioning Elements: These have different types of fastening devices and it is used to secure jig or fixture to machine at the proper position.

Indexing Elements: It is not always provided. But for many workpieces, it is indexed for different positions to order perform machining operations for different surfaces or different locations. In some cases these elements have to incorporate in jig or fixture.

Types of Jigs and Fixtures

Types of Jigs

- Template jig

- Plate jig

- Channel jig

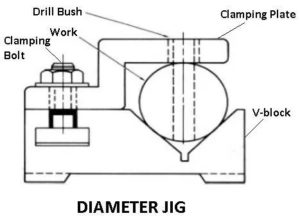

- Diameter jig

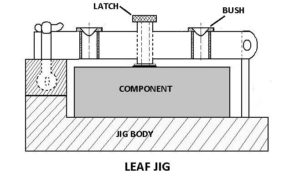

- Leaf jig

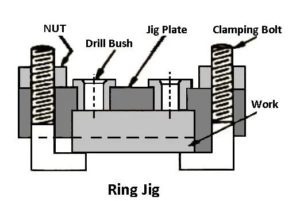

- Ring jig

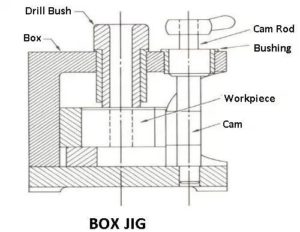

- Box jig

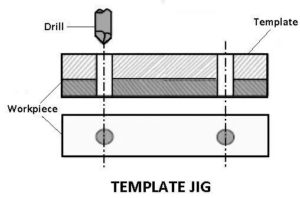

Template Jig

This is the simplest jig of all types. A plate 2 has holes at desired positions that serve as fixed on component 1 to be drilled. The drill 21 is guided through these holes of the template 2 and the required holes are drilled on the workpiece at the same positions with every other on a template.

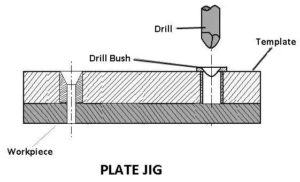

Plate Jig

A fixture is holds and positions the workpiece but does not guide the tool. And the jig hold, locate and guide the tool.

Fixtures have heavy construction and bolted rigidly on the machine table. The jigs are light in weight for better handling and clamping with the table is sometimes unnecessary.

Fixtures are used for handling work in milling, grinding, planning or for turning operations. And the jigs are used for holding work and guiding the tool particularly in drilling, reaming or tapping operations.

The plate jig is an improvement of template jig by incorporating drill bushes on a template. This plate jig is fit on drill holes on large parts for maintaining accurate spacing with each other.

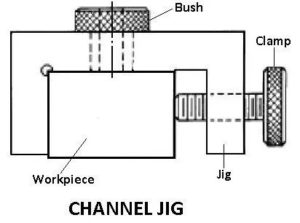

Channel Jig

The channel jig is shown in the above image. This is a simple type of jig with a channel-like cross-section. Component 1 is fitted within channel 4 and it is located and clamped by rotating knurled knob 5 and it is guided via drill bush 3.

Diameter Jig

The diameter jig is shown in the above image. This is used for drill radial holes on cylindrical or spherical workpieces. Work 1 is placed in fixed V-block 6 and then clamped by clamping plate 7 and is locate the work. This tool is guided through drill bush 8 and is set radially with the work.

Leaf Jig

This has a leaf or a plate with 13 hinged on a body at 11 and leaf may swing open or close on work for loading or loading purposes. This work 1 is located by buttons 10 and clamped by set screws 12. Drill bush 3 guides the tool.

Ring Jig

The ring jig is for drill holes on circular flanged parts. Workpiece we clamped securely on drill body and holes are drilled by guiding the tool via drill bushes.

Box Jig

It has a box-like construction and the components are located by buttons 18. The work 1 is clamped by rotating cam handle 19 and also locates it. The drill bush 3 guides the tool. Box jigs are employed to drill with a number of holes on a component from different angles.

Read Also: What is CNC Machine?Types of Fixtures

- Turning fixtures

- Milling fixtures

- Broaching fixtures

- Grinding fixtures

- Boring fixtures

- Indexing fixtures

- Tapping fixtures

- Duplex fixtures

- Welding fixtures

- Assembly fixtures

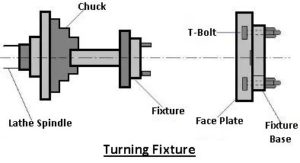

Turning Fixtures

For the standard job, the workpiece can easily hold for devices like chucks and collects between center and mandrels or faceplates. It is hard to hold irregular shape components and hard to hold them correctly.

The simple odd shape jobs can hold in a chuck and by proper adjustment of jaws in the four-jaw chuck with using shaped soft jaws. If the workpiece has complicated shape has to hold in the proper position for turning fixtures. The fixture is mounted on the nose of the machine spindle on a faceplate and the workpiece held them.

Image Source

The fixtures have to provide a counterweight or balance the unbalance fixture. Fixtures have to carefully designed and has to be rigid and minimum overhang the grip for workpiece firmly. It should not carry any dangerous projections for machine operators or tools or both should able to provide proper support for thin and weak sections of a workpiece in operation.

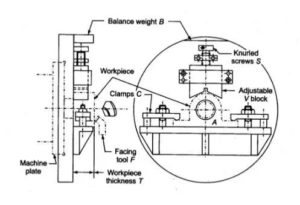

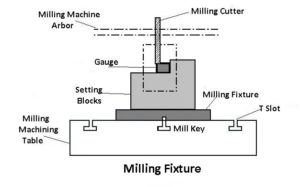

Milling Fixtures

These are used to milling for performing different milling operations on the workpiece. This fixture is located on a table of the machine and it is secured by bolts and nuts.

The table is shifted in a set of proper positions to relate to a cutter. The workpiece is placed at the base of the fixture and clamped before starting the operation.

As the cutting forces are quite high and also intermittent. The proper location of the fixture on machine table is achieved with the help of two tenons and it provides under a fixture base. These enter a T-slot of the table to provide at the required location. The fixture base can be secured to the table by T-bolts and nuts.

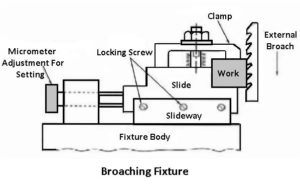

Broaching Fixture

These are used for different types of broaching machines to locate hold and support workpieces in operations like broaching operations like keyway broaching, hole broaching, etc. This uses a clamping plate as a fixture for internal pull-type hole broaching.

Grinding Fixture

There are different forms of fixtures are used to grinding machine to locate and hold and support the workpiece during operations. These fixtures may standard work-holding devices, such as chucks, mandrels, chuck with shaped jaws, magnetic chucks, etc.

The vertical surface grinder with a rotary table will have a rotary fixture secured to its table. A plain or string fixture may provide on a surface grinder with a reciprocating table. The drill grinding attachment is an example of a standard fixture for grinding of drill geometry.

The fixture should have designed for supply and exit of coolant, mounting of wheel dressers and should be properly balanced if it is a rotating fixture.

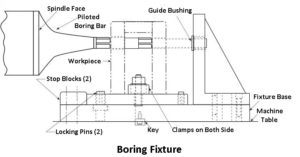

Boring Fixture

This operation can perform in one of the two ways

Keeping the boring bar (tool) stationary and feeding the touting workpiece on the bar.

Keeping the workpiece stationary and feed the rotating boring bar into work.

This incorporates with the principle of drilling jig and the boring bar is guided through the pilot bush. This fixture is referred to boring jigs and another design facilitates holding the workpiece in an incorrect position which relative to the boring bar.

This fixture has almost every common principle of jigs and fixtures design and their construction need not be sturdy as of the milling fixtures as they never have to bear as heavy cutting loads involved in milling fixtures as they never have to bear a heavy cutting loads use in milling operations.

Read Also: Milling Machine

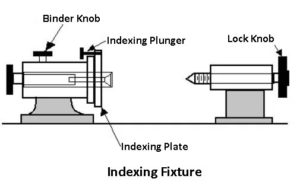

Indexing Fixture

Many workpieces need machining on the different surface so after machined the surfaces are evenly spaced.

This component needs to be indexed equally as many surfaces are machined. The holding devices like jigs and fixtures are used mainly to carry a suitable indexing mechanism. The fixture having a device known as an indexing fixture.

Tapping Fixture

This tapping fixture is designed specially for a position and secures identical workpiece for cutting internal threads for drills holes. The odd shape and unbalance workpiece need this type of fixtures especially when tapping operation is carried out on a mass scale for such components.

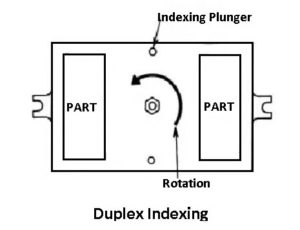

Duplex Fixture

It works the same as its name as it holds two similar components at the same time and facilitates machining for these components at two separate stations. One workpiece machined at one station.

Both the operations performed similarly or differently according to requirements. After completion of machining at both stations, the fixture is indexed through 180 degrees so the first component is shifted to the second station for the second operation and it finishes component to the first station.

After that, the finished component is uploaded here and replaced by a fresh component and the first operation is performed on it. The cycle keeps repeating and with this, the mass production of an item can be done at high speed.

Welding Fixtures

The welding fixture is carefully designed for holding and support to various components to be weld in proper places and to prevent distortions in welded structures. The locating element need to be careful and clamping has to be light but the placement of clamping element to clear of the welding area. This fixture should b stable and rigid for withstanding the welding stresses.

For many cases the preferable and common practice to first tack weld the structure for holding it in welding jig and then transfer to hold fixture for full welding. This is helpful in reducing the chances of distortion and fixture is subjected to lesser stresses.

Assembly Fixture

The function of the assembly fixture is to hold different components together in a proper relative position at the time of assembling. There are two or more steel plates are held together in relative positions and then riveted.

This is used for holding the components for performing mechanical operations and it is known as mechanical assembly fixtures. Also, there are different types of fixtures where the components are held for joining and this welding is assembly fixtures for hot joining.

Difference Between Jigs and Fixtures

These are the differences between jigs and fixtures.

The fixture holds the workpiece but does not guide the tool. The jig hold, locate and guide the tool.

Fixtures are heavy in construction and bolted rigidly on the machine table and jigs are light in weight for better handling and clamping with a table is unnecessary.

Fixtures are used for holding work in milling, grinding, planning or for turning operations where jigs are used for holding work and guiding the tool and generally in drilling reaming or tapping operations.

Advantages of using Jigs and Fixtures in Mass Production

- This eliminates the making out, measuring and other setting methods before machining.

- This increases the machine accuracy as the workpiece is automatically located and the tool is guided without making any manual adjustment.

- It is possible to make identical parts and also these parts are interchangeable. This also helps in assembly operation.

- This increases the production capacity as there is a number of workpieces machined in a single set up and in some instance, a number of tools may made operate simultaneously. The handling time is less as it has a quick setting for locating the work. Speed, feed, and depth to cut for machining can increase due to high clamping rigidity of jigs and fixtures.

- This reduces the operator’s labor as there are less handling operations.

- A semi-skill operator can operate the setting operations of the tool and work is machined which saves labor costs.

- This minimizes the expenditure on quality control of finish products.

- It minimizes the overall cost of machining by making fully or partly automating the process.

Advantages of Jigs and Fixtures

- This increases the machining accuracy as the workpiece is automatically placed and a tool is guided without making any adjustments.

- This increases the production capacity as there are many workpieces can machine with single set up and for some instances, there is a number of tools that can operate simultaneously.

- Handling time is reduced due to setting and locating work.

- speed, feed and depth of cut for machining can increase high clamping rigidity of jigs and fixtures.

- It can produce identical parts and are interchangeable and this helps in assembly operation.

- This eliminates the marking out, measuring and other setting methods before machining.

- This reduces the labor cost and consequent fatigue handling operations and is minimized and simplified.

- The semi-skill operator can perform operations as other setting operations of tool and work is mechanized and saves labor cost.

- This reduces the expenditure of quality control to finish products.

- It reduces the overall cost of machining by fully or partly automize the process.

Applications of Jigs and Fixtures

Applications of Jigs

- Drilling

- Reaming

- Tapping

Applications of Fixtures

- Milling

- Grinding

- Planning

- Turning

- Shaping

This is the information about jigs and fixtures, the difference between jigs and fixtures, advantages of jigs and fixtures and applications.

🔔We hope this information will help you. For more new information click on the notification button and get regular updates from Unbox Factory.

Now if you find this information helpful, share it with your friends, family, and colleagues.

If you like this post, let us know by comment below, if you want to add-on information about this topic, comment the information. We will consider the information if it is relevant.

Thank you for reading.