Contents

What is a Reciprocating Compressor?

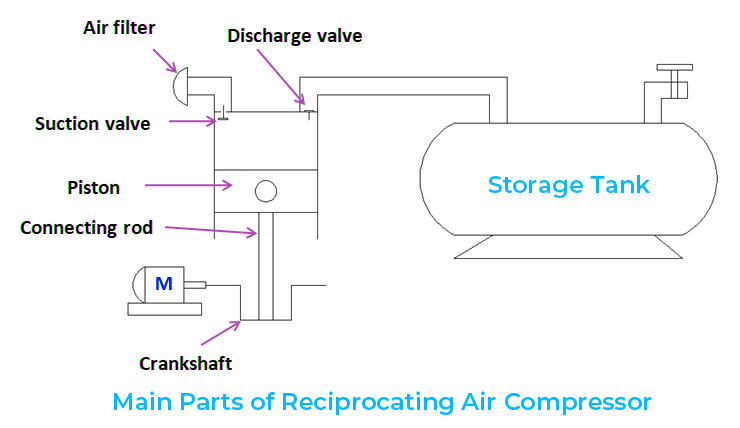

The reciprocating compressor is a positive displacement air compressor where the air is sucked in a chamber and it is compressed with a reciprocating piston. A reciprocating air compressor is a positive displacement compressor as air is first sucked in a chamber and compressed by decreasing the area of the chamber and the area is decreased by a piston.

Working Principle

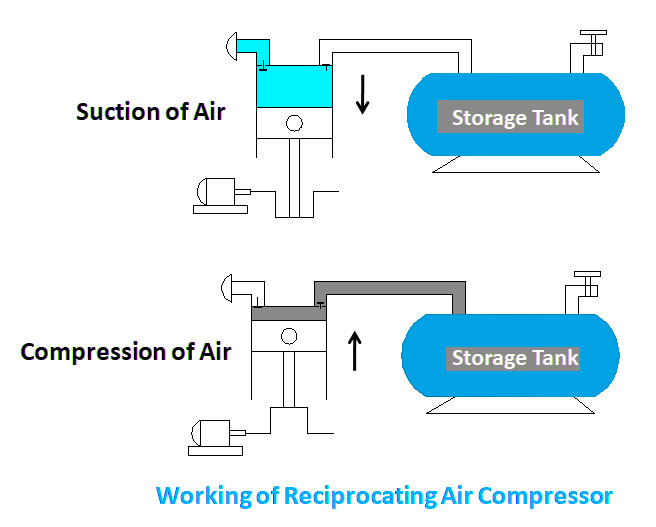

In the reciprocating air compressor, the piston moves to BDC and air is sucked into a cylinder from the atmosphere and moves it to the TDC. The compression of air starts and increasing and pressure is also increasing. After reaching the limit of the pressure the discharge valve is open and the compressed air is flowing through to the storage tank.

Piston: It has reciprocating motion in the cylinder and it compresses the air.

Cylinder: The air is compressed in the cylinder.

Connection Rod: This connects the piston and crankshaft.

Crankshaft: This is connected to the shaft of the electric motor and transfers rotary motion to the piston.

Suction valve: Air is sucked through a suction valve when the piston moves to BDC.

Discharge valve: Compressed air is discharged through the discharge valve to the storage tank.

Working of Reciprocating Compressor

The reciprocating air compressor is powered by an electric motor or by diesel/gas engines.

When the power in on, the electric motor starts rotating and rotates the crankshaft which attached to it and the piston starts moving the to and fro motion inside a cylinder.

The piston is moved downward the air from the atmosphere enters into the cylinder chamber.

After reaching to BDC the piston start moving upward and the compression of air starts and its pressure tends to increase.

After reaching the set pressure the discharge valve is open and through it, the compressed air is transfer to a storage tank where it can be used.

Different types of Reciprocating Air Compressor

There are

- Single Acting

- Double Acting

- Single-stage Air Compressor

- Double stage air Compressor

1. Single Acting

The single-acting reciprocating air compressor has only a single side of the piston and it is used for compression of air and another side is connected to the crankcase and it is not used for compression.

2. Double Acting

In the double-acting type of reciprocating compressor, the sides of the piston are used for compression of air. On the one side, there is suction and compression takes place on the other side. Both the suction and compression take place on every stroke of the piston.

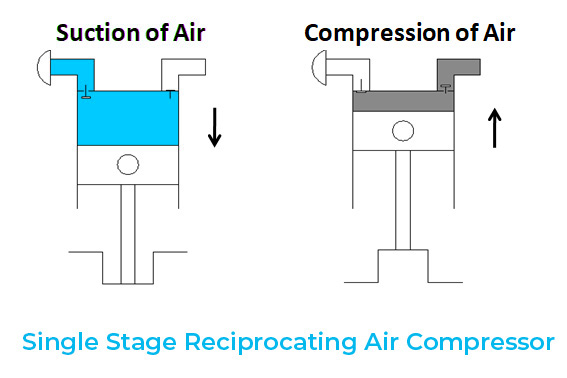

3. Single Stage air Compressor

The single-stage reciprocating air compressor, the compression of air takes place in a single cylinder. In this, the air sucks from the atmosphere are first stroke and in the second stroke, it compresses the air and delivers it to the storage tank.

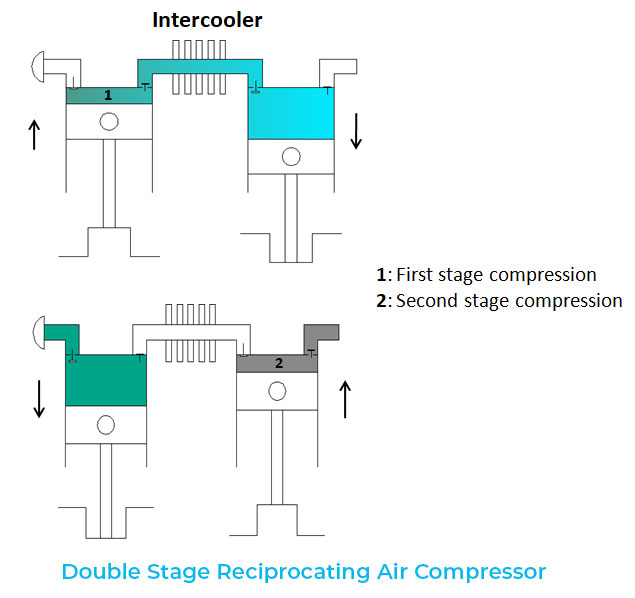

4. Double stage air Compressor

In the double stage air compressor, the compression takes place in two stages. In the first stage, the air is compressed in one cylinder and after that, it transferred to the second cylinder for the next compression. And in the end, the compressed air is stored in a tank.

This is the information about a reciprocating compressor, how does a compressor work and what is a compressor.

🔔We hope this information will help you. For more new information click on the notification button and get regular updates from Unbox Factory.

Now if you find this information helpful, share it with your friends, family, and colleagues.

If you like this post, let us know by comment below, if you want to add-on information about this topic, comment the information. We will consider the information if it is relevant.

Thank you for reading.