Contents

Lancashire Boiler – Parts, Working, Construction and More

The Lancashire boiler is working on the principle of a heat exchanger. This is a shell and tube type heat exchanger where the exhaust gases flow through the tubes and water flows through shell.

Heat is a transfer from exhaust gases to water via convection. This is a natural circulation boiler where natural current flows the water inside the boiler.

Parts of Lancashire Boiler

- Water level indicator

- Pressure gauge

- Safety valve

- Steam stop valve

- Feed check valve

- Blow off cock

- Manhole

- Fusible plug

- Grate

- Fire door

- Ash pit

1. Water Level Indicator

This indicates the level of water in the boiler and it is in front of the boiler. There are two water level indicators in the boilers.

2. Pressure Gauge

The pressure gauge measures the pressure of steam inside the boiler and it is fixed in front of the boiler.

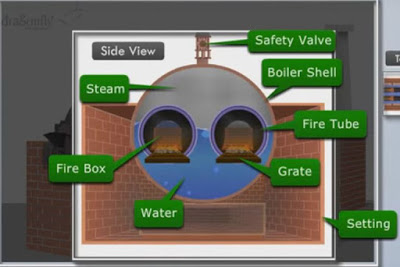

3. Safety Valve

The safety valve is a very important device as it ensures the safety of the boiler from being damaged by excessive steam pressure.

4. Steam Stop Valve

The purpose of the steam stop valve is to prevent and allow the flow of steam from the boiler to the steam pipe.

5. Feed Check Valve

The function of the feed check valve is to control the flow of water from the feed pump to the boiler for preventing the backflow of water from boiler to the pump.

6. Blow off Cock

Its function is to eliminate the sediments deposited at the bottom of the boiler when the boiler is in operation.

7. Man Hole

It is the place in the boiler where a man can enter into a boiler for cleaning or repairing.

8. Fusible Plug

The function is to put-off the fire in the furnace of the boiler when water levels fall below the unsafe level.

9. Grate

The grate is a floor used to burn the coal.

10. Fire Door

A fire door is used to burn fuel inside or outside the boiler.

11. Ash Pit

It is used to collect ash after burning the fuel.

Various Mountings and Accessories of Lancashire Boiler

- Economizer

- Air pre-heater

- Superheater

- Feed pump

1. Economizer

In the economizer, it is heating the feed water and is recover heat in flue gases. It is placed in the path of gases and it improves the overall efficiency of the boiler.

2. Air Pre-heater

It is an accessory that recovers the heat in the exhaust gases by heating the air to the furnace of the boiler. This improves the thermal efficiency of the boiler.

3. Superheater

It is used in superheating steam generated in the boiler. The main purpose is to raise the temperature of saturated steam without any change in pressure.

4. Feed Pump

It is required to force the feed water at high pressure into the boiler.

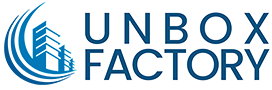

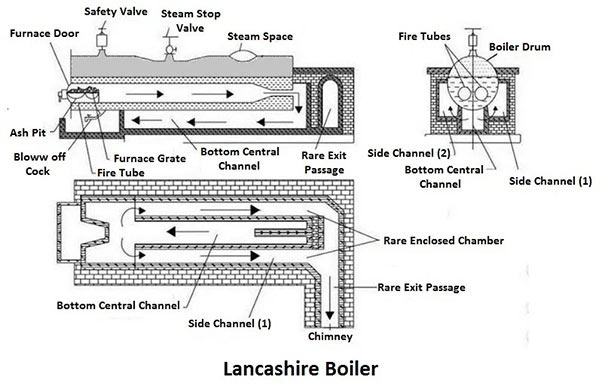

Lancashire Boiler Construction

The Lancashire boiler is similar to the shell and tube type heat exchanger. This consists of a large drum having a diameter up to 4-6 meters and 9-10 meters in length. The drum has two fire tubes of a diameter of 40% of the diameter of the shell and the water drum is located over bricks.

There are three spaces between drum and bricks one is at the bottom and the other two are shown in the Lancashire boiler diagram. Flue gases are pass through fire tubes ad side and bottom space.

The water level inside the drum is always above the side channels of flue gases for more heat transfer to the water. The drum is filled with water and upper half-space for steam. A furnace is placed at one end of the fire tubes inside the boiler.

The low brick is at grates and it prevents unburned flue and ash to flow in the fire tubes. This boiler has necessary mountings and accessories like economizer, superheater, safety valve, pressure gauge, water gauge, etc.

Working of Lancashire Boiler

The Lancashire boiler has a horizontal cylindrical shell and it is filled with water surrounding with two large fire tubes.

There is a cylindrical shell and it is placed over brickwork and this creates several channels for the flow of hot flue gases.

The solid fuel is entered through a fire door and after that, it is burnt over grate at the front end of each fire tube.

There is a small arc shape brickwork that is there and at the end of the grate to deflect the flue gases upward and prevent the entry of burning coal and ashes into the interior part of fire tubes.

This fire tubes are slightly conical at the rear end for increasing the velocity of hot flue gases.

The hot flue gases are allowing to pass through the downward channel at the front end of the fire tubes. These gases pass-through side-channel towards the rear end of the fire tube and finally exit from a chimney.

The dampers are on each side for regulating airflow.

There is a feed check valve and it is used to feed the water uniformly to the boiler shell.

After starting the boiler, the water starts converts into steam by absorbing heat from flue gases. Steam is stored at the upper portion of the boiler where the anti priming pipe is separate the water from steam. So, the steam stop valve receives the dry steam for various purposes.

The manhole is at the top and bottom of the shell and it is to clean the boiler.

There is a bow-off valve and it is to remove the mud which is settled down and also used for cleaning the boiler.

Advantages

- This boiler has high thermal efficiency and it is about 80 to 90%.

- Has easy operating

- Has the ability to meet the load requirement

- Easy maintenance

- It generates a large amount of steam and more reliable

- Low electric consumption due to natural circulation

Disadvantages

- This is a low-pressure type boiler so it cannot produce high-pressure steam

- Hard to maintenance in brickwork

- Has limited grate area due to small diameter of flue tubes

- Steam production rate is low about 9000 kg/hr

- Corrosion may occur in water legs

Applications

- The Lancashire boiler is used to drive steam turbines, locomotives, marines, etc.

- Lancashire boiler is also in various industries like the paper industry, textile industry, sugar industry, Tyre industry, etc.

This is the information about Lancashire Boiler, parts, application, advantages and disadvantages and how it works.

🔔We hope this information will help you. For more new information click on the notification button and get regular updates from Unbox Factory.

Now if you find this information helpful, share it with your friends, family, and colleagues.

If you like this post, let us know by comment below, if you want to add-on information about this topic, comment the information. We will consider the information if it is relevant.

Thank you for reading.