Contents

- 1 Cochran Boiler | Parts, Working, Advantages, Diagram

Cochran Boiler | Parts, Working, Advantages, Diagram

First What is Cochran Boiler?

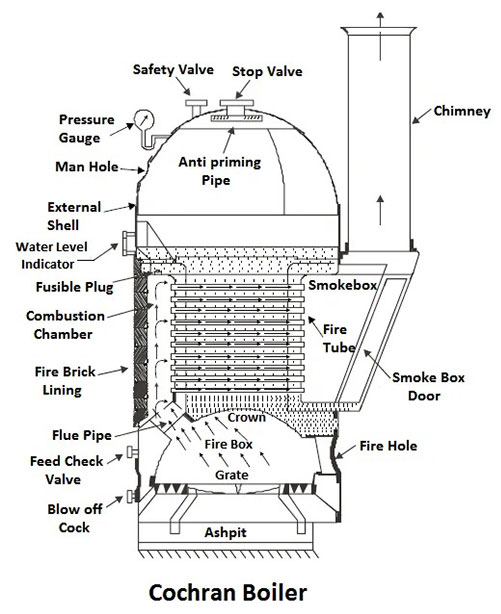

The Cochran boiler is vertical, multi-tube boiler generally used for small capacity steam generation. Cochran boilers are made in different sizes of evaporative capacities ranging starting from 150 to 3000 kg/hr. and working pressure up to 15 bar.

There is an external cylindrical shell and a firebox in the Cochran Boiler. The shape of the shell and firebox is hemispherical and the hemispherical head of the boiler provides maximum space and strength for withstanding the pressure built up in Cochran Boiler. Also, the hemispherical crown of the firebox helpful to resist intense heat.

This is the Cochran Boiler Diagram.

The firebox and combustion chamber are connected via a short pipe. The flue gases from the combustion chamber flow to the smokebox via a number of tubes. These gases from smokebox exhaust through a chimney. There are firebricks in the combustion chamber to withstand intense heat.

There is a manhole near the top of the crown on the shell for cleaning. At the bottom of the firebox for feeding grate and coal via fire hole and it is kept closed by a fire door.

Read Also: Lancashire BoilerParts of the Cochran Boiler

1. Boiler Shell

The boiler shell is made of steel plates into a cylindrical form and it is riveted or welded together. The ends of the shell are closed by endplates. The boiler shell should have enough capacity to store water and steam.

2. Combustion Chamber

The combustion chamber is below the boiler shell for burning the fuel to generate steam from the water in the shell.

3. Grate

The grate is a platform in the combustion chamber where fuel is burnt. The grate is generally a cast-iron bar and there is space between them so the air can pass through it. The surface area of the grate where fire takes place called a grate surface.

4. Furnace

The furnace is above the grate and below the boiler shell and in the furnace, the fuel is burned.

5. Fire Tubes

The fire tubes are the horizontal tube between the combustion chamber. The flue gases from the combustion chamber flow to the smokebox via a number of fire tubes. These fire pipes are used to exchange heat from hot flue gases to water.

6. Fire Hole

It is at the bottom of the combustion chamber for firing fuel inside the furnace.

7. Chimney

The chimney is provided at the top of the boiler and it is connected to the smokebox. These exhaust gases are coming out from fire tubes and pass through smokebox and exhaust through a chimney.

8. Man Hole

The manhole is for cleaning, repairing and inspecting of the boiler shell.

9. Flue Pipe

Firebox and combustion chamber is connected through a short pipe and these pipes are called flue pipes. The hot flue gases from the grate flow into the combustion chamber via flue pipe.

How does Cochran Boiler work?

- First, the coal is fed to grate via a fire hole for a burn.

- The ash formed in burning is collected in ash-pit below the grate and it removes manually.

- The hot gases from the grate pass through the combustion chamber to horizontal fire tubes and transfer the heat to water by convection.

- Exhaust gases out from fire tubes pass through smokebox and exhaust to the atmosphere via a chimney.

- There is a door in the smokebox for cleaning the fire tunes and smokebox. The Cochran boiler has a working pressure of 6.5 bar and a steam capacity of 3500 kg/hr.

Accessories and Mountings of Boiler

1. Water Level Indicator

The water level indicator is an important fitting in the boiler and it shows the water level inside the boiler. The water level indicator is a safety device and upon it the safe working of the boiler depends.

2. Pressure Gauge

The pressure gauge measures the pressure of steam inside the boiler and it is the fixed front of the steam boiler.

3. Safety Valve

The safety valve is installed in the steam boiler to prevent the explosions due to the high internal pressure of steam. The safety valve ensures the safety of a boiler from damage due to excessive steam pressure.

4. Stop Valve

It is used to control the flow within the boiler and stop it when required.

5. Cock or Blow off Valve

A blow-off valve is used to remove periodically the sediments deposited at the bottom of the boiler as the boiler is in operation and to empty the boiler it is to be cleaned or inspected.

6. Feed Check Valve

The feed check valve controls the flow of water from the feed pump to the boiler and also prevents the backflow of water from a boiler to pump when pump pressure is less than the boiler pressure or when the feed pump ceases to work.

7. Fusible Plug

The function of the fusible plug is to put-off the fire in the furnace of the boiler when the water level falls below an unsafe level to avoid the explosion and this takes place to overheat of tubes and shell.

What are the Advantages of Cochran Boiler?

- It has a low initial installation cost

- Requires less floor area

- Easy operation and handle

- Transportation is easy

- Can work on all types of fuels

What are the disadvantages of the Cochran Boiler?

- It has a low rate of steam generation

- Difficult to inspection and maintenance

- Required high room head for installation as have a vertical design

- Has limited pressure range

Applications

- The Cochran boiler is used in a variety of process applications in various industries

- Used in chemical processing divisions

- Pulp and paper manufacturing plants

- Used in refining units

Also, the Cochran boiler is used in power generation plants where large quantities of steam from 500 kg/s with high pressures approx. 160 bar and high temperatures reach up to 550o C.

Features of the Cochran Boiler

- There can use any type of fuel in Cochran Boiler

- This is suitable for small capacity requirements

- It has about 70% of thermal efficiency with coal firing and about 75% thermal efficiency with oil firing

- The ratio of grate area to heating surface area varies from 10:1 to 25:1

FAQs

Here are some FAQs of Cochran Boiler:

What is Cochran Boiler and Classification?

The boiler is a close system where water is heated at critical temperatures to produce steam for different purposes.

- Fire Tube Boiler

- Water-tube Boiler

Which type of Cochran Boiler is?

Cochran boiler is a fire tube boiler.

How much of steam produced from Cochran Boiler?

It has a low production of steam compared to other boilers. The Cochran boiler produces 500 kg/hr or more.

This is the information about Cochran Boiler, Cochran Boiler parts and how it works.

🔔We hope this information will help you. For more new information click on the notification button and get regular updates from Unbox Factory.

Now if you find this information helpful, share it with your friends, family, and colleagues.

If you like this post, let us know by comment below, if you want to add-on information about this topic, comment the information. We will consider the information if it is relevant.

Thank you for reading.