Kaplan Turbine – Parts, Working, Advantages, Disadvantages, Application

The Kaplan turbine is an axial flow reaction turbine with adjustable blades. The Kaplan turbine was developed by Viktor Kaplan in 1913, he was an Austrian professor. According to his design, there are automatically adjusted propeller blades and automatically adjusted wicket gates for obtaining efficiency in a wide range of water flow and water level.

The Kaplan turbine is also known as the propeller turbine and it is the next version of Francis Turbine. This can be capable of working at low head and high flow rates efficiently which is hard for Francis turbine. Kaplan turbine works more efficiently with the head range in 10 to 70 m.

What is Kaplan Turbine Working Principle?

As it is the reaction turbine, the reaction force of leaving water is used to turn the runner of the Kaplan turbine. In this turbine the water flows through twisted blades and a lift force is generated in the opposite direction of leaving water and it lifts the force and this rotates the blades.

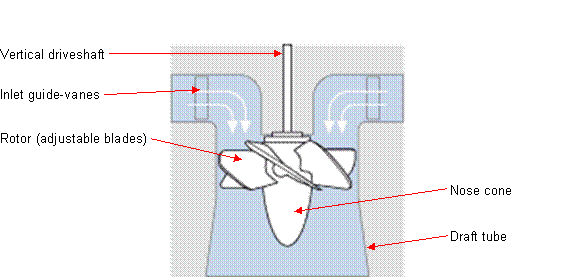

What are the Main Parts of the Kaplan Turbine?

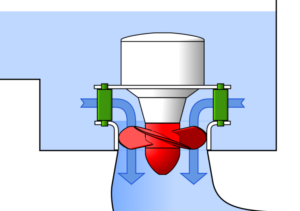

The main parts of this turbine are shown via the Kaplan turbine diagram.

1. Scroll Casing

This is a spiral type of casing with a decreasing cross-section area. First, the water is entering into scroll casing then it moves to the guide vanes and to the runner blades. The casing protects the runner, runner blades, guide vanes and other parts of the turbine from external damage.

2. Guide Vane Mechanism

The guide vanes are used to direct the water to runner blades smoothly by decreasing its swirl velocity. If the guide vanes are absent the turbine cannot work efficiently and the efficiency of the turbine is decreased. Guides in the Kaplan turbine are adjustable. The opening and closing depending on the demand of the power requirement. If more output is required, it opens wider to allow more water to hit blades of the rotor and when there is low power output is needed it closes itself to minimize the flow of water.

3. Runner Blades

The runner is a very important part of the turbine. The shaft is connected to the generator. Runner of this turbine has a large boss on which the blades are attached and blades of the runner are adjustable to an optimum angle for maximum power output. The blades of the Kaplan turbine have a twist with its length. One question is why the blades of runner in the Kaplan turbine have a twist? The answer is the runner blades have a twist with its length in order to have an optimum angle for a cross-section of blades to achieve greater efficiency.

4. Draft Tube

The draft tube is used to increase the pressure of fluid or water exit from the turbine. The turbine has an increasing cross-section area. The draft tube is only used in reaction turbines and increases the pressure of water which leaves the runner blades. As the water at the exit of the turbine has low pressure and if the pressure is not increased the backflow of tailrace water takes place and this could damage the turbine. To increase the pressure of exiting water the draft tube is used. This converts the kinetic energy of water into pressure energy as it passes through the draft tube and the pressure of water is increasing.

The draft tube has to increase the pressure of water to an extent which is always greater than the pressure of tailrace water and this prevents the backflow of water from tailrace to the turbine. If this does not happen this causes the cavitation and it may damage the turbine.

Working

Water is entered into scroll casing from pen-stock. After that, the water moves into scroll casing and guide vanes direct the water to the runner blades. These vanes are adjustable and it can adjust itself according to the required flow rate. The blades start rotating due to the reaction force of water. Kaplan turbine has adjustable blades. The water enters into the draft tube from runner blades where the pressure energy and kinetic energy is decreased. After that, the kinetic energy is starting converting to pressure energy and this increases the pressure of water and discharges through trail race. These rotations are connected to the shaft of a generator for electricity production and for other mechanical work.

Read Also: Francis TurbineAdvantages of the Kaplan Turbine

- This can work more efficiently at lower water head and high flow rates.

- Kaplan boiler is smaller in size.

- This turbine is easy to construct and required less space.

- The efficiency of the Kaplan turbine is very high than other hydraulic turbines.

Disadvantages of Kaplan Turbine

Cavitation is a major problem in the turbine.

This problem is solving with the use of a draft tube and using material like stainless steel for runner blades reduces this cavitation problem.

Application

The Kaplan turbine is used for power generation where water is available at low head and at higher flow rates.

This is the information about the Kaplan Turbine, parts, application, advantages and disadvantages and how it works.

🔔We hope this information will help you. For more new information click on the notification button and get regular updates from Unbox Factory.

Now if you find this information helpful, share it with your friends, family, and colleagues.

If you like this post, let us know by comment below, if you want to add-on information about this topic, comment the information. We will consider the information if it is relevant.

Thank you for reading.